Vertical - Horizontal Machining Center

Hyundai WIA's machine tools series

VERTICAL MACHINING CENTER

I-CUT SERIES

Vertical Machining Center

- Max. 24,000rpm direct connection high-speed main spindle application (i-CUT400M)

- Rigid tapping of 6,000rpm ensures optimum tapping capability

- Servo motor is applied on the ATC to reduce tool change time

- Z-axis Roller LM Guide applies travel safety improvment

- Best-in-class all axis 56m/min (2,205 ipm) rapid traverse rate

- Machining area expanded to best-in-class 450mm (17.7″) Y-axis travel (i-CUT450T)

- Latest HYUNDAI-iTROL & FANUC controls with user convenience improvemen

I-CUT SERIES

Vertical Machining Center

- Max. 24,000rpm direct connection high-speed main spindle application (i-CUT400M)

- Rigid tapping of 6,000rpm ensures optimum tapping capability

- Servo motor is applied on the ATC to reduce tool change time

- Z-axis Roller LM Guide applies travel safety improvment

- Best-in-class all axis 56m/min (2,205 ipm) rapid traverse rate

- Machining area expanded to best-in-class 450mm (17.7″) Y-axis travel (i-CUT450T)

- Latest HYUNDAI-iTROL & FANUC controls with user convenience improvemen

KF-B SERIES

Vertical machining center

- Box guideways for exceptional feeding during heavy duty cutting

- High-powered, high-torque main spindle for superb heavy duty cutting

- Main spindle with gear drive for high-power and high torque (BT50

Option) - Latest Servo ATC for highly efficient tool exchanging

KF-B SERIES

Vertical machining center

- Box guideways for exceptional feeding during heavy duty cutting

- High-powered, high-torque main spindle for superb heavy duty cutting

- Main spindle with gear drive for high-power and high torque (BT50

Option) - Latest Servo ATC for highly efficient tool exchanging

KFII SERIES

Vertical machining center

- High-precision machining by improved spindle quality

- High-speed roller type LM guide in all axes

- Enhanced chip processing capabilities by applying the upper-type conveyor

- Various motors and columns provided for customized machining

- Improved user convenience by applying the latest controller of FANUC

KFII SERIES

Vertical machining center

- High-precision machining by improved spindle quality

- High-speed roller type LM guide in all axes

- Enhanced chip processing capabilities by applying the upper-type conveyor

- Various motors and columns provided for customized machining

- Improved user convenience by applying the latest controller of FANUC

KF-BM SERIES

Vertical machining center

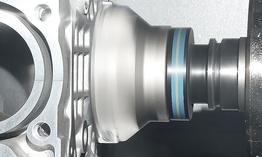

- Built-in spindle for a high-quality mold

processing - Excellent vibration absorption through box

guideways in all axes - Decrease of travel load with semi-air-floating

slide way - Prevent vibration fundamentally by seperated

column and magazine

KF-BM SERIES

Vertical machining center

- Built-in spindle for a high-quality mold

processing - Excellent vibration absorption through box

guideways in all axes - Decrease of travel load with semi-air-floating

slide way - Prevent vibration fundamentally by seperated

column and magazine

HI-MOLD SERIES

Vertical machining center

- High-speed LM guide in all axes

- Highly accurate main spindles with ultra precision angular contact bearings

- Built-in main spindle for processing high quality mold products

- Built-in 5-axis table to satisfy various processing needs (“5A” Type)

- Hyundai WIA mold package delivers optimal processing of mold parts

HI-MOLD SERIES

Vertical machining center

- High-speed LM guide in all axes

- Highly accurate main spindles with ultra precision angular contact bearings

- Built-in main spindle for processing high quality mold products

- Built-in 5-axis table to satisfy various processing needs (“5A” Type)

- Hyundai WIA mold package delivers optimal processing of mold parts

HORIZONTAL MACHINING CENTER

KH-SERIES

horizontal machining center

- Largest work area in its class with maximum processing size of 1,900 (74.8″) and 1,500mm

(59″) height - High-torque 8,000 and 4,500rpm spindles available

- Big Plus #50 2 Step Geared Spindle

- Spindle Oil Cooling System for high accuracy

- Shuttle Type Automatic Pallet Changer

- Box Guides on All Axis for Superior Rigidity

- Y axis box guideways with 8 face contact

HS4000 II

horizontal machining center

- High-performance 10,000rpm built-in spindle

- All-axis shaft cooling type ball screw

- Application of the largest tool in its class

- Rotary turn APC for high speed pallet change

- Best-in-class rapid traverse rate of 50 m/min (1.969 ipm)

- Adopted the latest controller of FANUC 31i B PLUS

HS4000 II

horizontal machining center

- High-performance 10,000rpm built-in spindle

- All-axis shaft cooling type ball screw

- Application of the largest tool in its class

- Rotary turn APC for high speed pallet change

- Best-in-class rapid traverse rate of 50 m/min (1.969 ipm)

- Adopted the latest controller of FANUC 31i B PLUS

HS II SERIES

horizontal machining center

- 15,000rpm high-performance built-in spindle

- X/Y/Z axis rapid traverse rate : 60m/min

- Ball screw shaft cooling system applied

- High rigidity 3-point support bed structure

- Large dia. Ø50 mm (2″) ball screw applied

Ring type magazine standard application

HS II SERIES

horizontal machining center

- 15,000rpm high-performance built-in spindle

- X/Y/Z axis rapid traverse rate : 60m/min

- Ball screw shaft cooling system applied

- High rigidity 3-point support bed structure

- Large dia. Ø50 mm (2″) ball screw applied

Ring type magazine standard application

KBN135

horizontal machining center

- Single unit bed for X and Z axis for ultra-precision (KB135)

- Movable column structure for high-load, heavy duty cutting needs (KB135C)

- Selectable X and Y axis of up to 1,000mm (39.3″) and 500mm (19.6″) respectively

- 3-step gear drive main spindle for heavy duty cutting

- Optimal boring capability with W-axis maximum travel of 700mm(27.5″)

- Equipped with standard linear and rotary scales for ultra-precision

Download Our Technical File

We offre technologies first class